About Lensee Automation

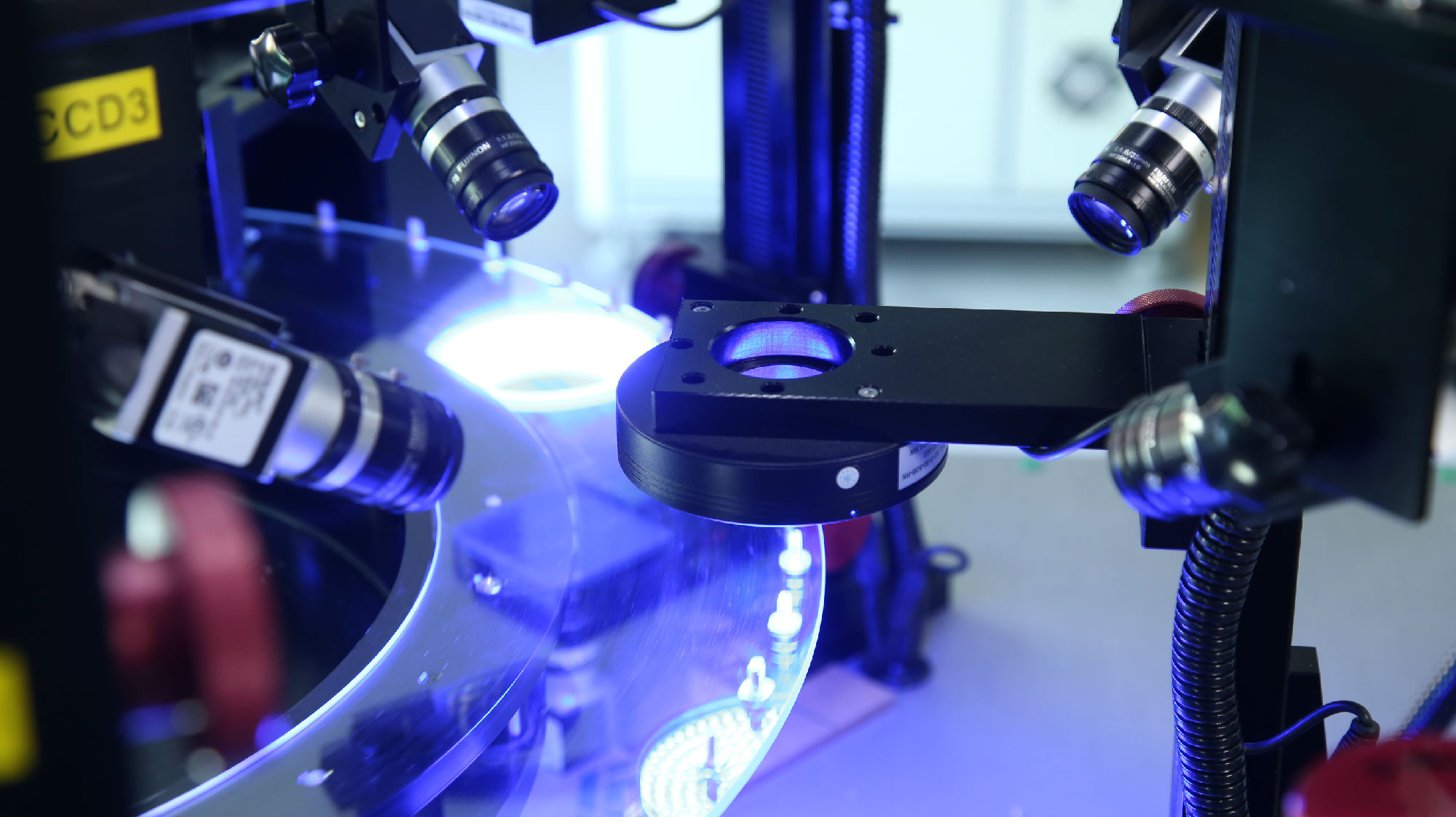

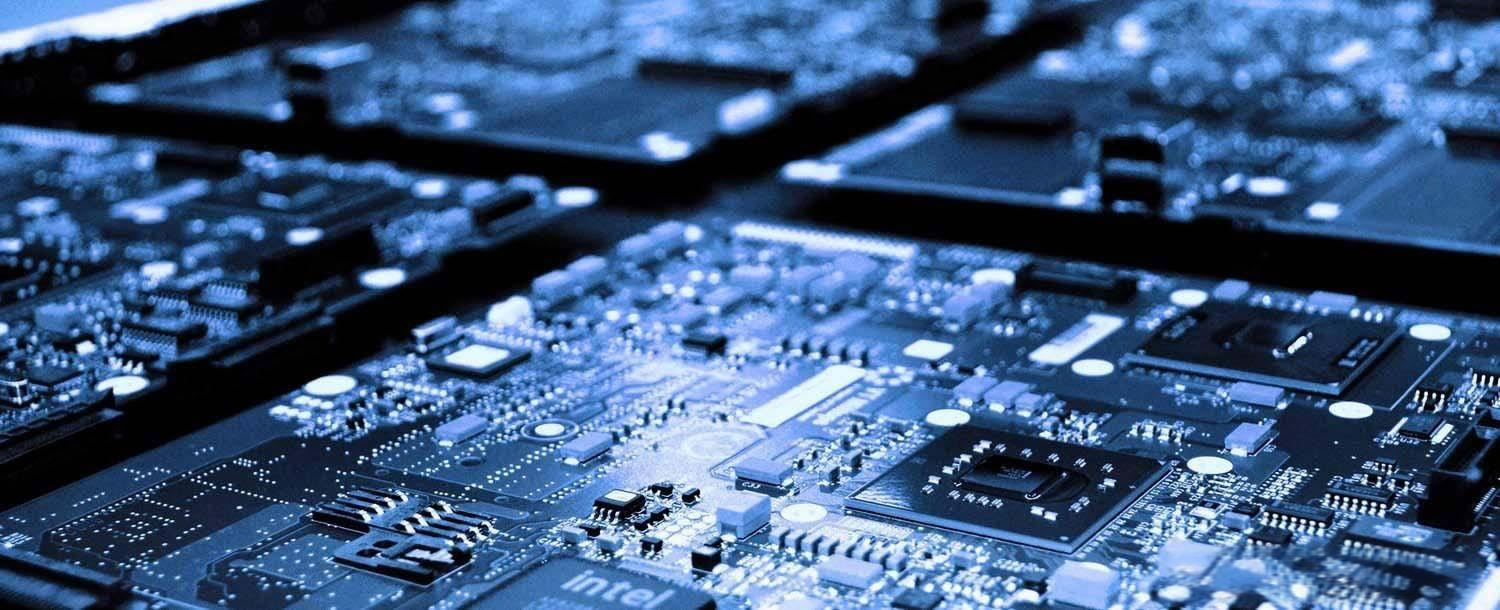

Fusing AI Vision with Automation to Elevate Industrial Quality and Efficiency. Lensee Automation specializes in highly customized AI vision inspection equipment and automation solutions for industrial manufacturing. We integrate AI and automation to improve yield, reduce cost, and boost throughput—delivering stable, scalable, and continuously optimized systems.

Founded in 2019, Lensee Automation has grown to a team of 200+ professionals, with R&D accounting for 35% of the organization. Our operations span an 8,000 m² facility housing engineering, assembly, and testing areas—enabling rapid development, validation, and reliable delivery at scale.

Our Value Proposition

- Outcome‑driven: Designed around key KPIs—yield, throughput, cost, safety, and traceability.

- Scenario‑centric: Tailored hardware, software, and algorithms to your real factory environment and quality standards.

- Long‑term reliability: Stable, scalable solutions with continuous optimization from deployment through operations.

Core Advantages

- Full‑stack engineering: Software, AI algorithm, mechanical, electrical, and optical teams working as one.

- End‑to‑end customization: Tight coupling of equipment, vision, algorithms, and industrial systems to speed up delivery.

- Industrial‑grade performance: Tuned and validated on real production lines for accuracy, speed, and stability.

- Rapid iteration and upgrades: Backed by an in‑house assembly and testing workshop.

What We Do

- Non‑standard Customized Equipment & Solutions: Bespoke inspection machines and automated lines covering optics, motion, control, vision, and data systems.

- Customizable Software Platforms: Three proprietary apps tailored by features, UI, and algorithms.

- End‑to‑End Turnkey Service: Requirement analysis, solution design, manufacturing, software/algorithm development, integration, commissioning, and maintenance.

Customizable Software Platforms

- AI Deep Learning Tagging & Training App: Distributed labeling, augmentation, experiment tracking, model versioning.

- Zero‑code / Low‑code Vision Platform: Drag‑and‑drop flows, device I/O, PLC/MES connectivity, dashboards, deployment.

- Defect Verification App: Human‑in‑the‑loop review, misclassification audit, feedback to models.

How We Work

- Discover: Process study, sample analysis, KPI definition.

- Design: Optical/mechanical/electrical/algorithm co‑design with simulations and trials.

- Deliver: Manufacturing, software development, FAT/SAT, operator training, go‑live.

- Optimize: On‑site tuning, data‑driven iterations, predictive maintenance.

Our Commitment

- Fit‑for‑purpose solutions aligned with your process and quality standards.

- Transparent milestones, measurable outcomes, and on‑time delivery.

- Long‑term partnership with lifecycle support and continuous upgrades.

Contact Us

Contact us to obtain more information about our AI software products, vision inspection and automation solutions, and quotations for your processes.

Lensee Automation—Empowering exceptional manufacturing with customizable smart vision and automation!

WhatsApp: +1 (623) 271 5363

Tel: +86 13360854135

Email: milohwae@gmail.com